Shop

| Specification | Details |

|---|---|

| Mixing Capacity | 1000 L (standard IBC container) |

| Speed | 200 rpm |

| Torque | 34 Nm |

| Power Supply | 3-phase, 380V/415V, 50/60Hz |

| Material (Wetted) | SS316L / SS304 (food & pharma grade) |

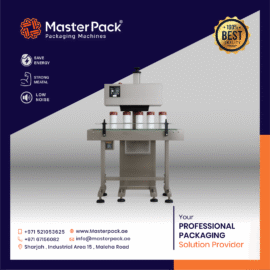

| Input Power | 230V ±10%, AC, 10A, Single Phase |

|---|---|

| Line Speed | Max. 50 feet/minute |

| Cap Size | 20 – 120 mm |

| Net Weight | 150 kg (270 kg packed) |

| Dimensions | 650 × 600 × 1650 mm |

| Print Resolution | Up to 600 dpi |

|---|---|

| Print Speed | Up to 120 m/min (at 75 dpi) |

| Controller | 7-inch touch screen |

| Print Head | Modular, replaceable |

| Applications | Text, barcodes, QR codes, expiry dates, logos |

| Integration | Conveyor production lines |

| Workable Volume | 30 Gallons |

|---|---|

| Temperature | Up to 98°C (209°F) |

| Mixing Speed | 0–350 RPM (variable frequency) |

| Heater | 5kW immersion heater with thermostat |

| Motor | 1 HP SS motor with gearbox |

| Interior Finish | Electropolished 0.8 µm (food-grade) |

| Dimensions | 26″ L × 26″ W × 69″ H |

| Construction | Stainless Steel SUS304 / SUS316 |

| Platform Dimensions | 850 × 1450 × 1200 mm |

|---|---|

| Weight Capacity | Up to 15 kg |

| Detection Sensitivity | Fe: 0.8 mm, Non-Fe: 1.0 mm, SUS: 1.2 mm |

| Conveyor Speed | 10 – 60 m/min adjustable |

| Control System | Touch Screen PLC |

| Construction | Stainless Steel |

| Power Supply | 220V, 50/60Hz |

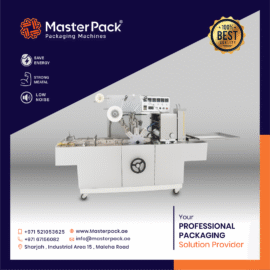

| Packing Material | BOPP film and tear tape |

|---|---|

| Speed | 30-100pcs/min |

| Compressed Air | ≥0.6mpa |

| Power supply | 220V 1Phase 50Hz |

| Motor | 0.75kW |

| Machine dimension | 2000 x 800 x 1400mm |

| Type | Packaging Production Line |

|---|---|

| Application | Drinks, Dairy, Detergent, Cosmetics, Oil, Tea, Food, Molasses, Auto Parts, etc. |

| Operation System | Touch Screen PLC Control |

| Capacity | 20–130 Cartons/Min |

| Power Supply | 220/380V 50Hz (Customizable) |

| Feeding Method | Manual or Automatic |

| Certification | CE |

| Production Output | 1200–8000 PCS/H |

| Transport Package | Wooden Box |

| HS Code | 8422301090 |

| Specification | Details |

|---|---|

| Lane Options | 4 / 6 / 8 / 10 lanes |

| Bag Width | 12–90 mm (depending on lanes) |

| Packing Speed | 30–50 bags/min/lane |

| Cutting Types | Flat, zigzag, continuous, or custom shapes |

| Optional Devices | Date coder, air-filling, tear notch device |

| Container Types | 200L Drums (Plastic/Steel), IBCs & Totes |

|---|---|

| Automation Type | Semi-Automatic (Top & Sub-Surface) |

| Fill Heads | 1 (Optional 2) |

| Filling Accuracy | Based on Weighing Scale |

| Viscosity Range | 0 – 100,000 CPS (Water to Toothpaste) |

| Frame Material | Carbon Steel (Optional Stainless 304/316) |

| Applications | Chemicals, Oils, Lubricants, Food & Hazardous Products |